GOOD VIEW Industrial Company Limited

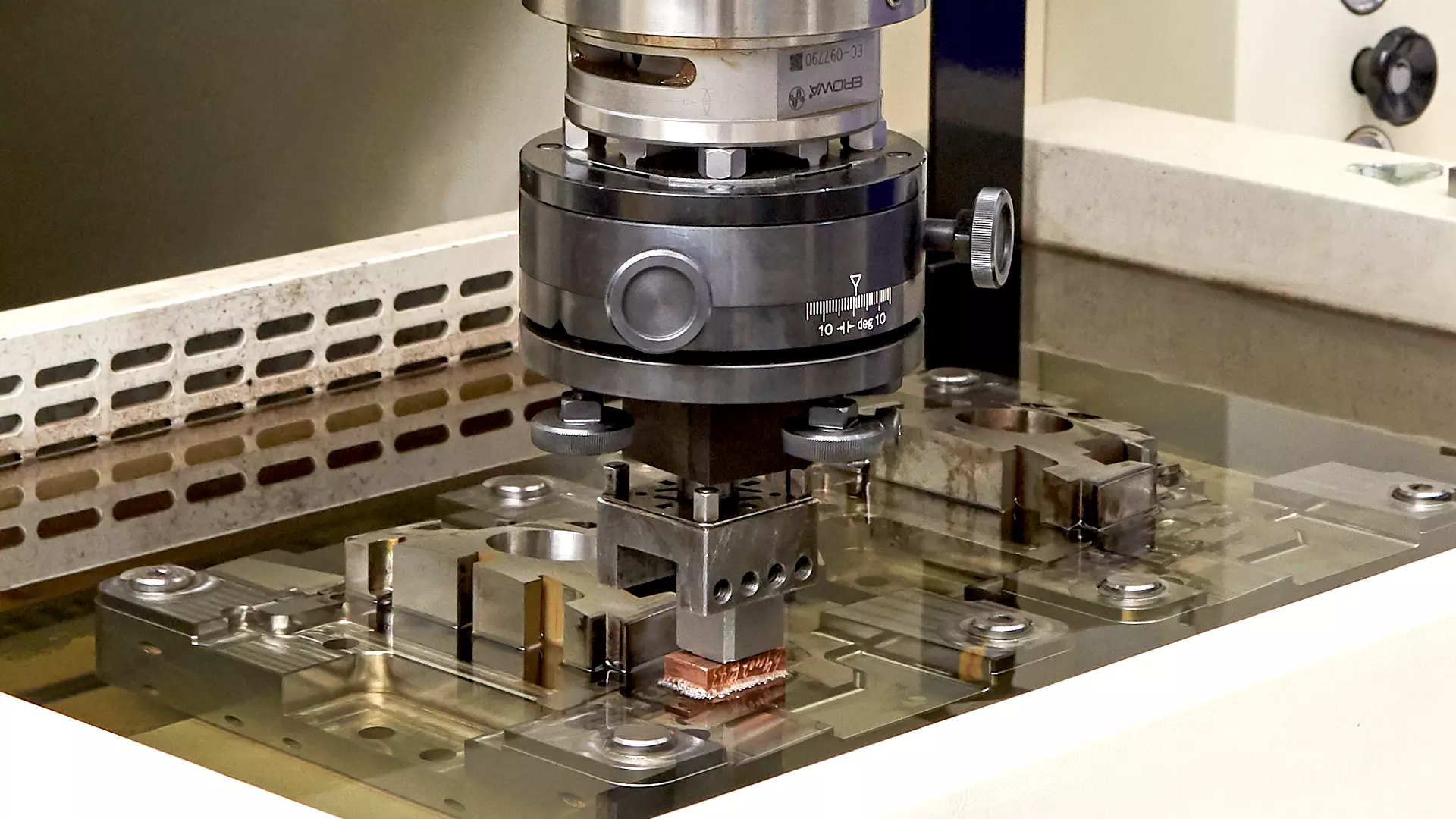

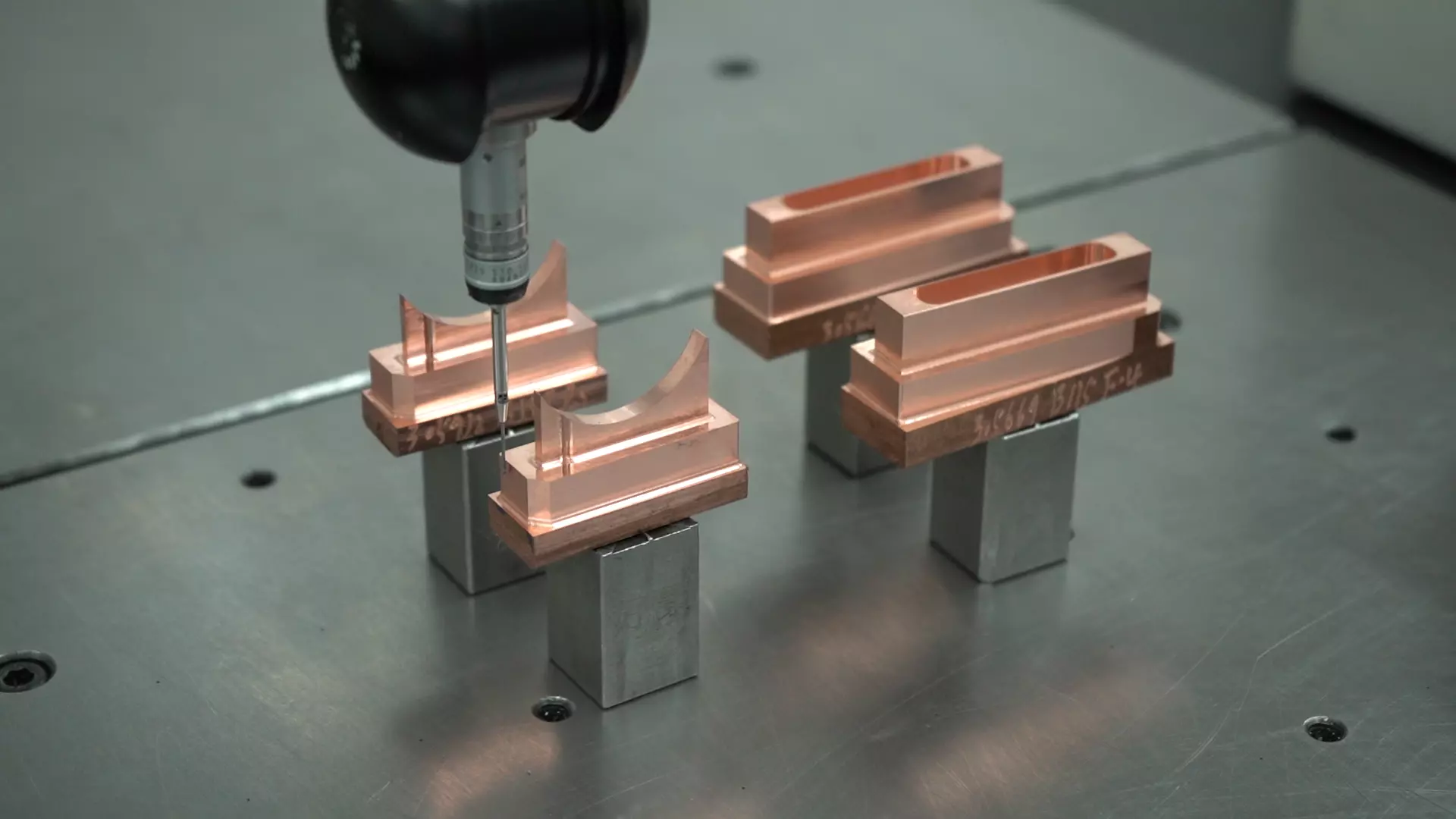

Good View’s experienced and skilled Tooling team is committed to building high-quality production tools not only for our in-house molding but as well for overseas Injection molders located all over the globe.

Time to market is essential for success of any project. We believe that communication is the key to successful execution of a project.

Our team of dedicated Project Managers are committed to coordinating, planning, management and execution of your projects in order to efficiently meet your project objectives.

Good View’s experienced and skilled Tooling team is committed to building high-quality production tools not only for our in-house molding but as well for overseas Injection molders located all over the globe.

Time to market is essential for success of any project. We believe that communication is the key to successful execution of a project.

Our team of dedicated Project Managers are committed to coordinating, planning, management and execution of your projects in order to efficiently meet your project objectives.

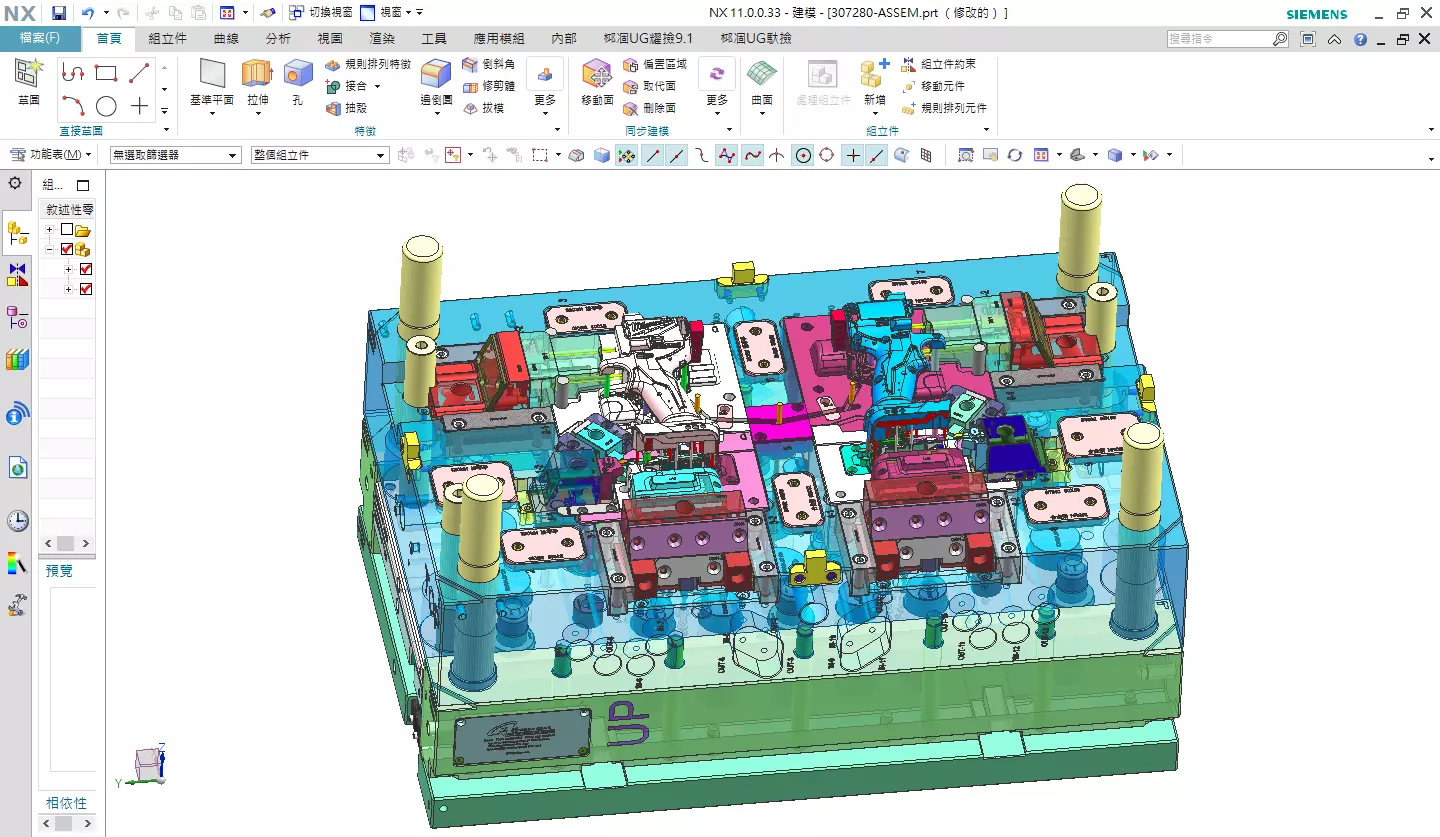

Perform DFM (Design for Manufacturability) analysis to ensure tooling and production friendly designs. After customer feedback on the DFM analysis reports, related modifications are made on the part design for clients’ approvals prior to start of tool manufacturing.

Good View is professional in making molds for overseas injection molders. Our strength is to customize our molds to meet clients’ own specifications. We currently produce 1200 molds per year, of which 20% are for export to North America, Europe and Japan.